Teak veneer faced plywood boards

Teak veneer faced plywood boards Specification

- Material

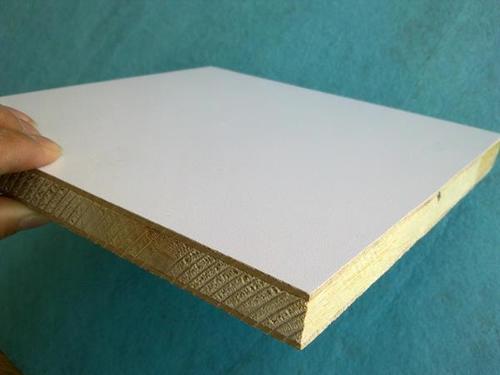

- Plywood Core with Natural Teak Veneer Face

- Type

- Veneer Faced Plywood Board

- Thickness

- Available in 4mm, 6mm, 12mm, 18mm, 25mm

- Application

- Furniture, Interior Panelling, Cabinets, Doors, Decorative Purposes

- Hardness

- Medium to High

- Surface Treatment

- Finished with Teak Veneer

- Feature

- Durable, Termite Resistant, Smooth Surface, Aesthetic Appearance

- Grade

- BWR/BWP (Boiling Water Resistant/Proof), Commercial Grade

- Finish

- Matte/Semi-Gloss

- Core Type

- Hardwood or Poplar Core

- Edge Profile

- Straight or Square Cut

- Density

- 500-700 kg/m³

- Manufacturing Process

- Hot Pressed with High Pressure

- Bonding

- Phenol Formaldehyde/ Urea Formaldehyde Resin

- Panel Size

- 8ft x 4ft (2440mm x 1220mm), Custom Sizes Available

- Moisture Content

- Less than 12%

- Usage

- Residential, Commercial, and Institutional Projects

About Teak veneer faced plywood boards

Name: Teak veneer plywood board sheets

Brand: LONSTRONG

Detail Spec:

1. Size: 1220*2440MM / 4'*8';

2. Thickness: 18MM;

3. Face/Back:Natural teak veneer laminated;

4. Core:Natural Albizia Falcata wood;

5. Feature:Natural wood,stable&strong nail holding,anti-scratch,eco-friendly;

6. Application:Furniture Cupboard, Office Furniture, Kitchen Cabinet, Office Table, etc;

7. Origin:Jiashan city,Zhejiang,China

Exceptional Quality for Diverse Uses

Our veneer faced plywood boards are engineered to offer optimal performance and appearance for furniture, paneling, doors, and decorative tasks. The combination of a strong hardwood or poplar core with a refined teak veneer face ensures a smooth surface finish, superior hardness, and lasting elegance for various interior projects.

Precision Manufacturing and Superior Durability

Each board is hot pressed under high pressure, using advanced bonding techniques with phenol formaldehyde or urea formaldehyde resin. This results in panels with excellent dimensional stability, durable bonding, and effective resistance against moisture and termites, making them ideal for use in demanding environments.

Versatile Sizing and Customization

Choose from industry-standard 8ft x 4ft (2440mm x 1220mm) panels or request custom sizes to fit unique design requirements. With thickness options ranging from 4mm to 25mm and straight or square edge profiles, our plywood is tailored to suit a wide variety of construction and interior design needs.

FAQs of Teak veneer faced plywood boards:

Q: How is the durability of teak veneer faced plywood ensured?

A: Durability is achieved through hot pressing with high pressure and bonding with quality phenol formaldehyde or urea formaldehyde resins. This process provides strong adhesion, resistance to termites, moisture, and results in a board suitable for rigorous residential, commercial, and institutional use.Q: What applications are ideal for this type of veneer faced plywood?

A: These plywood boards are perfect for furniture manufacturing, interior paneling, cabinets, doors, and other decorative interior purposes in both homes and commercial or institutional settings, thanks to their aesthetic teak veneer finish and robust construction.Q: When should one choose BWR/BWP grade plywood over standard options?

A: BWR/BWP grade plywood is recommended when superior water and moisture resistance is required, such as in areas prone to humidity or occasional water exposure, ensuring longevity and stability in various climatic conditions.Q: Where are these plywood boards typically sourced and supplied from?

A: These boards are manufactured, distributed, and exported primarily from China, with a network of dealers, wholesalers, traders, and suppliers catering to global residential, commercial, and institutional project demands.Q: What is the typical manufacturing process for these plywood boards?

A: The panels are produced by hot pressing multiple layers of hardwood or poplar veneers, bonded with phenol or urea formaldehyde resin, and topped with a natural teak veneer, resulting in a smooth, seamless, and highly durable finish.Q: How does the moisture content affect the performance of the boards?

A: Maintaining moisture content below 12% prevents warping, increases dimensional stability, and ensures the boards performance over time, especially in applications where consistent humidity is a concern.Q: What are the benefits of using these veneer faced plywood boards?

A: Users benefit from a strong yet visually appealing material that is moisture and termite resistant, easy to customize, and suitable for a broad range of interior projects, lending both practicality and elegance to any space.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furniture Block Boards Category

Block Board

Price 21 USD ($) / Square Foot

Minimum Order Quantity : 1150 Sheets

Surface Treatment : Melamine impregnated paper laminated

Material : Natural Albizia Falcata Core

Feature : Wear Resistant, Waterproof, Ageing Resistant

Thickness : 18 Millimeter (mm)

Red Oak Veneer Block Board

Price 19.80-21.60 USD ($)

Minimum Order Quantity : 1150SHEETS Sheets

Surface Treatment : Natural red oak veneer laminate

Material : Falcata wood core

Red Oak Veneer Laminate Furniture Block Boards

Price 19.60-21.80 USD ($)

Minimum Order Quantity : 1150sheets Sheets

Surface Treatment : Veneer Laminate

Material : Red Oak with engineered wood block board core

Feature : Other, Durable, termiteresistant, elegant wood grain

Thickness : Available in 18mm, 25mm, and custom sizes

LONSTRONG Block Boards

Price 20.60-21.50 USD ($)

Minimum Order Quantity : 1150sheets Sheets

Surface Treatment : Melamine Paper, Veneer, Laminated

Material : Poplar Wood

Feature : Other, Moisture Proof, Strong Screw Holding, Termite Resistant

Thickness : 18 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry